Oil Analysis

Oil Sampling and Oil Analysis

The reason to sampling the oil is providing excelent machine performance and reliability by checking oils situation and contamination level.

Based on the oil analysis results, benchmarks can be established and machines with critical levels are determined.

Where does an oil sample takes from?

In order to produce a representative sample, the oil must have a continuous flow through a marking tube, preferably upward. Sampling points located on the lower circumference of a pipe tend to allow particles in the sampling valve to accumulate.

A sample taken between the pump and the filter housing of an off-line filter is normally the worst contaminated part of the oil system, this is the part that best represents the total system contamination load and therefore.

These three things are necessary to take an oil sample:

- Glass bottle without any particules (200 ml)

- 5 liters of open oil container

- Swab

Before taking an oil sample follow steps carefully:

- Locate the oil container to the sampling valve

- Open and close valve for 5 times and keep it open

- Wash the pipe by draining to a liter container

- Open sampling bottle and pretend polish entering in it

- Locate the bottle under oil flow without touching sampling valve

- Fill the bottle nearly %80

- Close the bottle right after taking sample

- Shake the bottle, empty the container and refill the bottle

- Close sampling valve

- All samples must require reference number, machine reference number, machine brand and model, sampling location, date, oil type/oil brand.

Samples can only be collected from a machine that operates on normal temprature.

Method is very important in accordance to particle counting.

Oil Analysis: How do I read the data?

An oil analysis must require these things:

- Particle number

- Water cornet(ppm)

- Viscosity

- Acid level

- If the oil additive content is of remakable, the analysis should be included.

- 0.8 milipore membrane for sludge determination

Maximum values:

- Particle numbers: Oil cleanance must be arranged to the most sensitive component of the machine. For instance, If hydraulic systems uses servo valves, NAS class 6 or better should be used.

- Water: Water cornet is measures by PPM. 1 PPM=%0.0001. Basic water concentration shall never pass 300 PPM according to rules.

- Viscosity: Viscosity is measures by cSt. Typic oil viscosity for hydraulic is 32 cSt, 46 cSt and 68 cSt mg/KOH gr. Typic oil viscosity for lubrication oil is 220 cSt and 320 cSt. The oil viscosity can vary in intimal viscosity within a range of 25% or more.

- Acid level – Total acid number: Acidity level is determined by TAN mg/KOH. Every type of oil has its own maximum TAN value. As your oil supplier about your maximum TAN level. For hydraulic, maximum level of TAN is typically 1.0 mg/KOH gr. That means fresh oil shall start at the level of 0.2 mg/KOH gr.

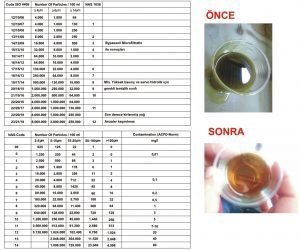

Standarts of particle counting

1. ISO 4406 Standart

ISO 4406/2000 classification of particle content has been made to facilitate comparison of particle content.

Sudden deterioration in an oil system is caused by large particles (> 14 microns) in the oil, whereas slower, progressive defects, e.g. wear and tear, are caused by smaller particles (4-6 microns). This is one of the reasons the particle reference sizes are set at ISO 4406/2000 at 4 microns, 6 microns and 14 microns.

Typical sample, each oil contains;

- 450 000 particle>4 micron

- 120 000 particle>6 micron

- 14 000 particle>14 micron

2. NAS 1638 Standart

NAS 1628 is an American standard that references the contamination load on the basis of fragmentation of different particle sizes for 5 to 15 microns, 15 to 25 microns, 25 to 50 microns, 50 to 100 microns,> 100 microns.

The difference is that NAS gives a detailed breakdown of different particle sizes that are greater than 5 microns.

Evaluation of the number of particles:

The ISO and NAS code obtained are an indication of the cleanliness of the oil in the system and can be verified in the contamination tables shown above.

Contamination guide for hydraulic and mineral oil systems:

- ISO 14/12/10 – NAS 4: Very clean oil. Best for all systems.

- ıSO 16/14/11 – NAS 5: Clean oil. Necessary for servo and high pressure hydraulic systems.

- ISO 17/15/12 – NAS 6: Slightly dirty oil. Standart hydraulic and mineral oil systems.

- ISO 19/17/14 – NAS 8: New oil for medium and low pressure systems.

- ISO 22/20/17 – NAS 12: Very dirty oil. It is not suitable for oil systems.

A cleaning goal must be specified for each oil-filled system. This is the basic requirement to guarantee reliability at the lowest cost.

A millipore membrane shows oil degradation if a 0.8 micron cellulose membrane is used.

Analysis frequency:

During the implementation phase of a condition monitoring system, analyzes should be conducted at least every six months to establish an information database.

Every oil system should have a log in which analysis results are recorded.

The logbook should also contain information about the oil type, oil change, separation, target ISO class code and oil analysis results.